One maintenance manager puts it this way:

“Our CMMS system and our Techs using it have not achieved the level of maturity for it to be a valuable tool. The Techs input insufficient levels of detail into our CMMS. Thus, needed data for Reliability Analysis (RA) would be inaccurate or lacking completely. As such, time would be wasted trying to perform useful RA. When we are able to get our CMMS to a level where your software will add value we will contact you.”

The perception that current CMMS procedures are “not mature enough” is a familiar one in maintenance departments. No matter how advanced our CMMS technology and related procedures grow, the right information in the right form for practical analysis eludes us. The solution seems always beyond the next bend in the road – the next project may finally solve the problem.

Unfortunately, CMMS procedures, as they are currently conceived, will never acquire the quality of data needed for systematic, fact driven, measurable improvement in asset reliability. A basic misunderstanding of data requirements has impeded progress in this area. Current procedures overlook two important attributes of a work order: the Failure Mode and and its Event Type. Cerrejón Coal removed the major impediment to reliability analysis enabling data by implementing a Living RCM (LRCM) process. LRCM solves a long standing maintenance information organizational problem, that of using the CMMS as an effective data source for analysis and improvement.

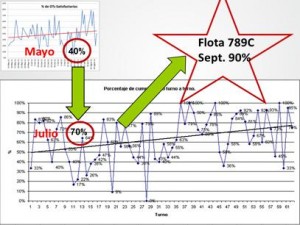

LRCM guarantees measurable results within months. For example, during a typical LRCM pilot project work order historical information in most maintenance departments will quickly attain a quality level of 90-95%, the minimum necessary for conducting effective Reliability Analysis. This performance metric tracks the percentage of new work orders satisfying the strictest criteria for reliability analysis and decision modeling.

The Living RCM method achieves success though a fundamental change in maintenance personnel’s understanding of the nature of data and its practical use. The culture of LRCM empowers techs, analysts, and engineers in several ways, for example, LRCM will:

- Eliminate guesswork and chronic inconsistency in work order data entry.

- Reduce the time and effort expended by technicians and supervisors in work order data entry.

- Refine continuously, the RCM knowledge base while integrating it into daily effective work reporting, selection, and planning procedures.

- LRCM will enable engineers to exploit powerful Reliability Analysis software and technology.

Decades of waiting and countless aggressive projects and expensive maintenance initiatives have promised but failed to deliver these benefits. Until the fundamental issues regarding the nature of maintenance related data have been addressed and resolved by LRCM, the wait will go on indefinitely.

© 2012, Murray Wiseman. All rights reserved.