A maintenance professional comments:

According to the definition that you provide, you would actually group inspections as CBM activities. This is semantics I think, but the term condition-based maintenance would make me believe that it relates to an activity that is prompted by analysis that indicates the condition is unsatisfactory for continued service. That is not the case for an inspection. The inspection is set at a frequency independent of the condition of the asset. The inspection is done to determine the condition and is set at an interval that is shorter than the expected P-F interval.

Thanks for this comment on “Inspection” v.s. “CBM task”. This certainly is semantics as  you point out. I think it’s unfortunate that the word “inspection” has become so fluid as to mean anything from a non-intrusive task such as taking a reading all the way up to a major overhaul of a gas turbine. RCM tries to pin down definitions and, therefore, specifies only five failure management policies as on this RCM course slide.

you point out. I think it’s unfortunate that the word “inspection” has become so fluid as to mean anything from a non-intrusive task such as taking a reading all the way up to a major overhaul of a gas turbine. RCM tries to pin down definitions and, therefore, specifies only five failure management policies as on this RCM course slide.

RCM doesn’t include “Inspections” on the list of policies. When the policies are stated as one of the options in the slide there is little ambiguity, although the opportunity to take readings and conduct tests would likely happen inside a TBM activity.

| A CBM task is an “inspection” that is carried out at regular intervals solely for the purpose of detecting a potential failure. |

Major inspections, overhauls, or shutdowns are primarily TBM activities although they will certainly contain many CBM tasks. Sometimes a CBM task is part of a checklist on a time based maintenance schedule that also includes service tasks (e.g. oil top up) as well as actual TBM tasks. Strictly speaking, those individual CBM tasks performed within a TBM checklist or overhaul should be considered CBM since the data they acquire would determine the need for additional maintenance.

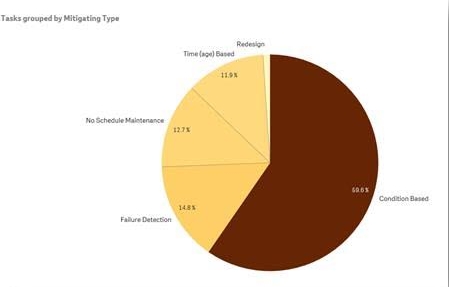

Because CBM “inspections” are carried out at regular intervals, some EAM people,  mistakenly, in my view, classify them as “TBM” which they often ambiguously call “PM”. One common disagreement among RCM consultants is related directly to this semantic issue. Some experts argue that CBM is appropriate for only 5-10% of failure modes. They arrive at this low percentage because they consider many CBM “inspection” tasks to be TBM. By my definition (in blue above) CBM covers a much larger chunk of the total maintenance effort pie. They (some consultants and authors) limit the definition of CBM to the more exciting techniques such as Vibration Analysis, Motor Current analysis, and so on. Whereas, to me (and Nowlan and Heap) even banal tasks such as taking a routine reading, or conducting a visual inspection for dirt in a panel would be CBM activities. This notion is further explored in the article Internal and external CBM variables.

mistakenly, in my view, classify them as “TBM” which they often ambiguously call “PM”. One common disagreement among RCM consultants is related directly to this semantic issue. Some experts argue that CBM is appropriate for only 5-10% of failure modes. They arrive at this low percentage because they consider many CBM “inspection” tasks to be TBM. By my definition (in blue above) CBM covers a much larger chunk of the total maintenance effort pie. They (some consultants and authors) limit the definition of CBM to the more exciting techniques such as Vibration Analysis, Motor Current analysis, and so on. Whereas, to me (and Nowlan and Heap) even banal tasks such as taking a routine reading, or conducting a visual inspection for dirt in a panel would be CBM activities. This notion is further explored in the article Internal and external CBM variables.

© 2016, Murray Wiseman. All rights reserved.