EXAKT is a set of software modules for accomplishing physical asset reliability from maintenance related data that is commonly available in an industrial organization. There are three EXAKT modules. They are listed in the following paragraphs:

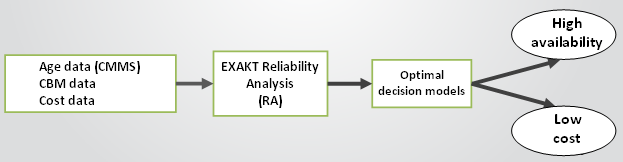

- EXAKT for Modeling. This is a Reliability Analysis tool that extends Weibull analysis to include Condition Monitoring and Process data. EXAKT for Modeling produces and tests Optimal Decision Models,. Decision Models (DMs) are rules for conducting a maintenance action based on an item’s current age and its condition as they are reflected in available databases. Optimal DMs generate decisions that are tuned to deliver the organizational objectives of high equipment availability at low cost and risk. The input to the software includes data from:

- The CMMS (for example, SAP, Maximo, Ellipse, or any work order database), and

- Condition monitoring and process monitoring systems and activities. These may include real time databases or historians, vibration sensors and data collectors, oil analysis results databases, and physical observations.The data requirements for EXAKT and its output are illustrated in the following diagram.

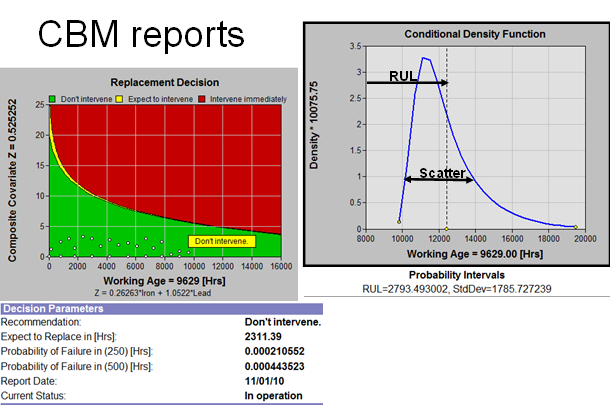

- EXAKT for Decisions. Once a decision model for a given equipment and its failure modes has been developed in the EXAKT for Modeling module the model will then be deployed as an automated intelligent agent by launching the EXAKT for Decisions module. This software module initiates a background process on the network that monitors designated databases containing the relevant data. The most recent entries in each relevant database are processed by the software which then produces a Remaining Useful Life Estimation (RULE), confidence limits, and a recommended action based on failure probability and the business factors included in the model. The following image illustrates the output from EXAKT for Decisions. The first diagram provides an optimal recommendation, either to intervene immediately (red), plan to intervene in a stated time period (yellow), or continue operation (green). The second diagram indicates the Remaining Useful Life (RUL) and the confidence interval, expressed here as a standard deviation. The results are reported in the CMMS.

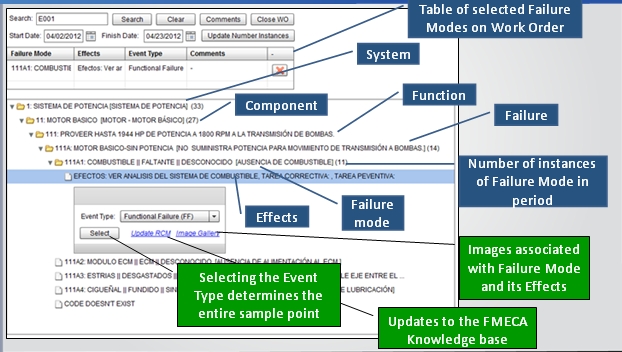

- EXAKT Living RCM (LRCM) User Interface (UI) and Process module. In order to achieve effective Reliability Analysis (RA) using powerful software such as EXAKT, the maintenance organization must ensure that accurate data is contained in the work order history. This is accomplished using the LRCM User Interface to the CMMS. When technicians and other maintenance personnel close work orders using the LRCM UI, the resulting maintenance historical records will contain data of the high quality required for RA. An example of the the LRCM UI is shown in the following image. By using the LRCM UI and its related procedures, the RULE and recommendations from EXAKT for Decisions will perform optimally in guiding day-to-day maintenance decisions. The software will empower the maintenance department engineers to maximize, in a verifiable way, the asset’s profitability as it relates to their maintenance strategy and activities.

© 2012, Murray Wiseman. All rights reserved.