Criticality Analysis may be applied at two levels of the RCM process. First, it may be used to sort or classify a large number of equipment assets as to their priority for analysis. Secondly criticality analysis may be applied to individual failure modes as in the FMECA process.

Criticality analysis when performed on failure modes can consume time in RCM review group sessions but may serve little purpose. Criticality analysis, as such, is not included in the JA1011 RCM specification (allowing organizations to use industry specific methods to quantify risk and priority associated with each reasonably likely failure mode). The UK Ministry of Defense Def Stan 00 45 method to perform Criticality Analysis may be applied at the failure mode level, and with minor alteration at the equipment level. The following paragraphs describe eight steps for performing criticality analysis on failure modes:

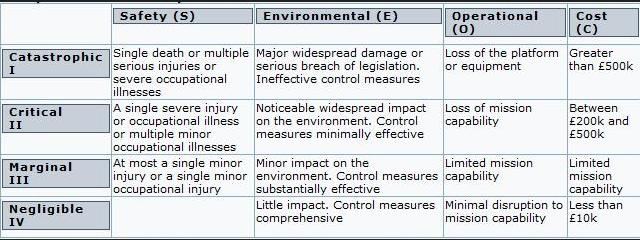

- Set up a hazard classification table for the categories of Safety, Environmental, Operational, and Cost (non-operational), for example:

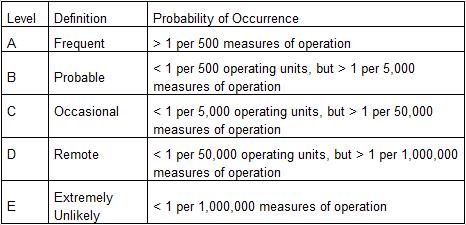

- Set up a probability of occurrence table, for example:

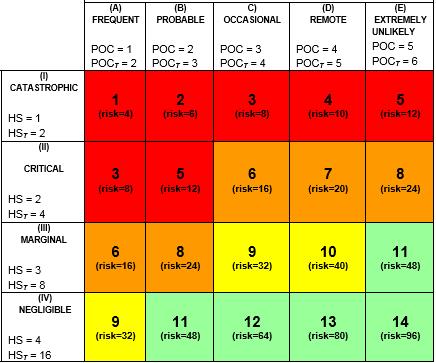

- Transform the tables of paragraphs 1 and 2 into into a “risk matrix”, each cell of which contains a “risk index” (a number between 1 and 14) by the following steps:

- Assign the probability of occurrence (POC) values 1, 2, …, 5 t0 the probability occurrences A, B, …, E respectively.

- Assign the hazard severity (HS) values 1, 2, …4 to the hazard classifications I, II, …, IV respectively.

- Transform POC and HS as follows:

- POCT = POC + 1, and

- HST = 2HS

- Place the values of POCT and HST in the horizontal header row and in the vertical header column of the criticality matrix of paragraph 8 below.

- Calculate the risk in each cell as Risk = POCT × HST

- Number the cells in left to right and top to bottom sequence, repeating the number when the risk equals that of a previously numbered cell. These numbers will be the “criticality indices”.

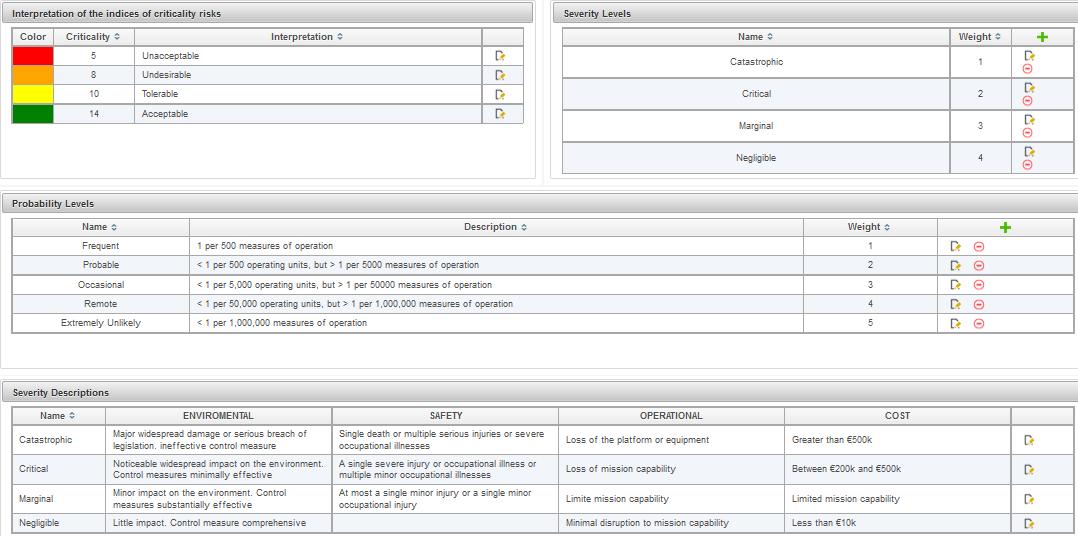

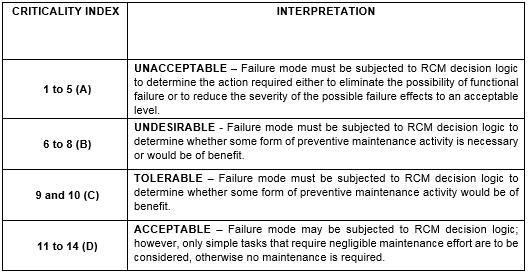

- Color code each cell according to the example risk classification table:

- The resulting criticality matrix appears as:

The main purpose of a criticality analysis exercise within the RCM analysis process is to prioritize failure modes for later review of its effects, likelihood, consequences, and mitigating task. For example, the failure modes with highest criticality, on, say a sea oil platform, would be reviewed first to ascertain that the scheduled task is still effective in mitigating the consequences of failure.

Criticality analysis configuration in Mesh LRCM

A numerical failure mode criticality determination must be preceded by a thorough Effects analysis where all reasonably likely events touched off by the failure mode are described. The Effects should describe what could happen at the component, system, and end item level, and even at the organizational or societal level if the consequences of failure merit such detail. The Effects description suffices for determining the consequences and mitigating task. For purposes of setting the mitigation task the criticality analysis step is unnecessary. However, the Effects description is essential before applying the criticality matrix . Some industries who are required to review all critical failure modes on a yearly or two-yearly basis in the light of changes to operating context use failure mode criticality analysis to prioritize that process.

As organizations adopt LRCM their reliability engineers will be made aware on a continuous basis of new information and knowledge emanating from work orders executed day to day. That information will prompt them to refine the RCM analysis, and re-examine task effectiveness. The Effects determine the consequences and the mitigating task more accurately than a criticality index. In other words the consequences and the effects dictate the maintenance plan.

The method of criticality analysis described here can also be applied, with minor changes in wording, to the entire RCM project preparation phase in order to select and prioritize equipment items for RCM analysis.

| A=1 | Frequent | > 1 per 500 measures of operation | |||

| B=2 | Probable | 1 per 500 operating units, but > 1 per 5,000 measures of operation | |||

| C=3 | Occasional | 1 per 5,000 operating units, but > 1 per 50,000 measures of operation | |||

| D=4 | Remote | < 1 per 50,000 operating units, but > 1 per 1,000,000 measures of operation | |||

| E=5 | Extremely Unlikely | < 1 per 1,000,000 measures of operation | |||

© 2011 – 2016, Murray Wiseman. All rights reserved.

- Local, Next higher level, End effects (69.2%)

- Effects (23.1%)

- The elusive P-F interval (23.1%)

- LRCM and HSE (23.1%)

- Deepwater Horizon (23.1%)

- Templates for speeding up RCM (RANDOM - 7.7%)

[…] Criticality analysis […]