A prominent mining operation uses the SAP maintenance module as their CMMS, As well they use the OSIsoft PI system. However, they admit that their data is messy, non-standardized, and unreliable as a result of a multitude of approaches and changes throughout the years. In other words, the “normal” situation. As a result of previous negative experience “RCM” is a BAD word in this maintenance organization. (FMEA or FMECA are ok.) What lessons learned can be drawn from LRCM experience that can shed light here?

Indeed there is nothing “special” about this organization’s inability to draw measurable value from their data in spite of having expended resources on state-of-the-art “data-centric” maintenance management and condition monitoring systems.

Lessons learned at sites currently implementing LRCM:

- Significant non-monetary investment is required by the reliability engineer in verifying daily the work order-to-knowledge base links and in updating the knowledge base.

- Investment by the technicians in distinguishing “What I did” and “What I found”. The latter is essential for determining the event type (Failure or Suspension) of each failure mode encountered when executing the work.

- Emphasize the return on the Technicians’, Engineers’ investments.

- Better and more analysis due to error free sample generation

- Less and less time required in completing the work order form. If the circumstances surrounding the failure mode are already well described in the Effects there is no need to repeat the same information on the work order. That knowledge is already linked to the work order. Thus as the knowledge base grows less effort is required.

- It is essential to keep the low level objectives front and center:

- Linking work orders to the RCM knowledge base

- Sample generation

- Refinement of the knowledge base

- Analysis

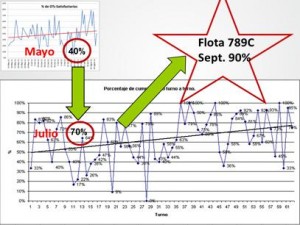

KPIs should track the progress of each of these fleet-by-fleet.

- Keep the communications flowing between the Engineers, Supervisors, and Technicians. In those discussions keep invoking the concepts of failure mode, suspension, and failure.

- Simplify and standardize the writing style of the work order free text.

- Provide examples of analysis based on samples where Suspensions and Failures are confused. Compare them with analysis of samples based on good discrimination of these concepts. Using the EXAKT conditional probability density plots and standard error in Remaining Useful Life Estimation (RULE) shows the advantage quite graphically.

© 2011 – 2018, Murray Wiseman. All rights reserved.

- Elevator description of LRCM (100%)

- What is a pilot project? (100%)

- RA requires LRCM (100%)

- Components of continuous improvement (100%)

- How much detail? (100%)

- Course brochure - Living RCM Certified (RANDOM - 100%)